Product Description:

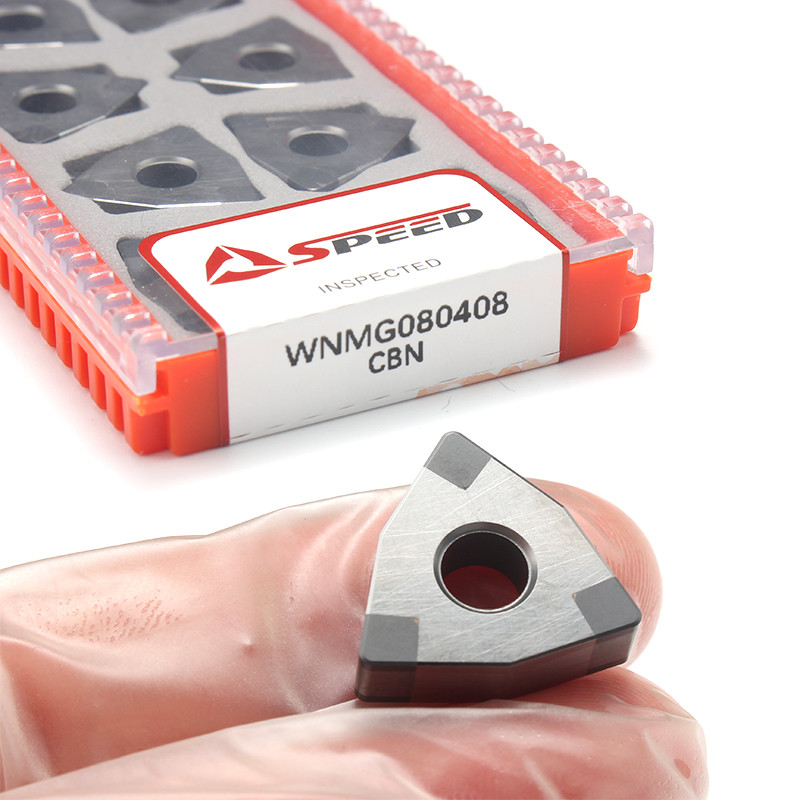

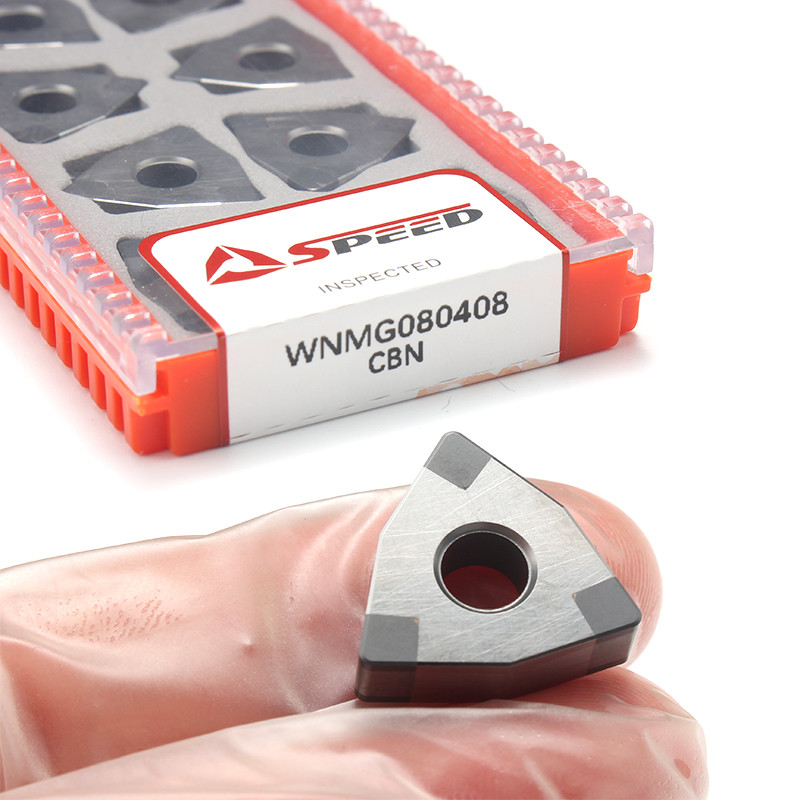

CCMT DCMT DCGT 060201 PCD Turning Inserts Cutting Tools CBN Diamond

Tip CBN Inserts For Metal Working

Features:

Polycrystalline diamond (PCD) and cubic boron nitride (CBN) Inserts

for Advanced Cutting

Polycrystalline diamond (PCD) and cubic boron nitride (CBN) inserts

are highly advanced cutting tools that can be used for machining

processes due to their unique material properties. The following is

a summary of the key features and applications of PCD and CBN

inserts.

Features of PCD Inserts:

- Material Hardness: PCD inserts are extremely hard and are ideal for cutting

non-ferrous materials.

- Wear Resistance: PCD's hardness contributes to excellent wear resistance, making it

appropriate for prolonged machining tasks with minimal tool

degradation.

- Thermal Conductivity: PCD has excellent thermal conductivity, aiding in heat dissipation

during machining, which helps maintain tool integrity and reduces

the risk of thermal damage.

- Surface Finish: PCD tools provide superior surface finish and dimensional

accuracy, essential for high-precision applications.

- Chemical Stability: PCD is resistant to chemical reactions and may be suitable for

machining materials that may be abrasive or reactive.

- Low Friction: Their low friction coefficient reduces the cutting forces needed,

which allows for high-speed machining.

- Versatility: PCD inserts can perform various operations like turning, milling,

and drilling, primarily on non-ferrous materials like aluminum,

composites, and plastics.

Features of CBN Inserts:

- High Hardness: CBN is the second hardest material after diamond, making CBN

inserts ideal for cutting hard ferrous materials, including

hardened steels.

- Wear Resistance: CBN exhibits excellent wear resistance, especially for high-speed

machining environments, just like PCD.

- Thermal Stability: CBN can withstand high temperatures without significant

degradation, which is advantageous for cutting applications like

those that generate high heat.

- Chemical Stability: CBN is chemically stable at high temperatures, which is crucial

for machining materials that may generate reactive conditions.

- Edge Strength: CBN inserts maintain edge integrity better than traditional

carbide tools in cutting hard materials, thus reducing the risk of

chipping or breaking.

- Cutting Efficiency: CBN tools allow for efficient chip removal and reduction in

machining forces, which may enhance productivity.

Applications:

PCD and CBN inserts have specific applications. PCD is better for

non-ferrous materials like aluminum, composites, and plastics. In

comparison, CBN excels regarding ferrous materials, which are

hardened steels. CBN inserts are thus ideal for machining hardened

steels and iron-based materials, making them a common choice in

automotive and aerospace applications.

Comparison:

Regarding cost, PCD tends to be more expensive due to the diamond

content and manufacturing process, making CBN somewhat less costly.

However, both inserts offer prolonged tool life compared to

conventional carbide due to their hardness and wear resistance.

Conclusion:

PCD and CBN inserts are irreplaceable components in the modern

machining industry, providing precision, efficiency, and superior

performance in their respective applications. Understanding the

unique features and benefits of each type can enable manufacturers

to choose the right inserts for their machining needs.

Technical Parameters:

The Technical Parameters of PCD and CBN Inserts

The technical parameters of PCD (Polycrystalline Diamond) and CBN

(Cubic Boron Nitride) inserts can vary based on their specific

application, geometry, coating, and manufacturer. However, some

common technical parameters are often evaluated when considering

these inserts. Here’s an overview of typically relevant parameters

for both PCD and CBN inserts:

PCD Insert Technical Parameters

- Material Composition: PCD inserts are made from diamond particles bonded with a metal

matrix, which may vary depending on the specific application.

- Hardness: Vickers Hardness is typically greater than 6000 HV, depending on

the composition and manufacturing process.

- Thickness: Common thickness ranges from 0.5 mm to 10 mm, depending on the

application.

- Grain Size: Average grain size can vary from 1 μm to several microns,

influencing wear resistance and toughness.

- Thermal Conductivity: Thermal conductivity is around 700-900 W/m·K, making it effective

for heat dissipation.

- Coating: Common coatings include PVD or CVD coatings may be applied to

enhance performance, depending on the material being machined.

- Edge Preparation: Sharpened or honed edges can enhance cutting performance in

specific applications.

- Geometry: Various shapes are available such as round, square, triangular,

and more, each optimized for particular cutting applications.

- Chip Breaker Design: Various chip breaker configurations can enhance chip control and

improve cutting efficiency.

CBN Insert Technical Parameters

- Material Composition: CBN inserts are typically made of cubic boron nitride in a solid

form, sometimes in combination with a binder such as cobalt or

ceramic.

- Hardness: Vickers Hardness is typically 4500 - 5000 HV, providing excellent

wear resistance for hard materials.

- Thickness: Common thickness is similar to PCD inserts, ranging from

approximately 0.5 mm to 8 mm or more based on specific

applications.

- Thermal Stability: CBN can withstand temperatures up to about 1000°C (1832°F) without

significant degradation.

- Coating: Common coatings often include TiN, TiC, or Al2O3 coatings, which

can enhance wear resistance depending on the application.

- Edge Preparation: Suitable edge preparations are used to optimize performance based

on the specific material and machining operation.

- Geometry: Various shapes are also available like square, round, and

octagonal, facilitating different types of machining operations.

- Chip Breaker Design: Various chip breaker geometries are used for controlling chip flow

and optimizing cutting conditions.

- Grain Size: Typically varies according to the manufacturing process and

intended use; finer grain sizes offer better edge stability.

General Considerations for Both Inserts

- Insert Size: Standard insert sizes follow the ISO metric system (e.g., ISO ISO

8885:1993) and ANSI standard (e.g., ANSI B212).

- Flank Wear Resistance: Measurement of flank wear resistance is critical for assessing

tool life. This is sometimes measured in microns (µm) after

standard machining tests.

- Cutting Edge Strength: The cutting edge strength is essential for evaluating performance

under different cutting conditions and materials.

- Application Information: Each insert is often designed for specific cutting operations

(turning, milling, etc.) and materials (aluminum, hardened steel,

etc.).

Conclusion

When selecting PCD or CBN inserts, it's essential to consider these

technical parameters in relation to the specific application,

workpiece materials, and machining conditions. Always refer to the

manufacturer’s specifications and guidelines to ensure the chosen

inserts meet the requirements of your machining operations.

Applications:

PCD and CBN inserts are essential components in many different

industrial processes, as they are specifically designed for

particular applications and materials. By comprehending the

particular characteristics of these cutting tools, manufacturers

are able to enhance their work procedures, improve efficiency, and

attain superb outcomes. To optimize results, it’s important for

users to select the right insert that suits the material to be

machined, the required tolerance, and the desired surface finish.

Having a thorough understanding of the properties of PCD and CBN

inserts is crucial for ensuring success when machining materials.

These cutting tools provide exceptional precision and durability in

a variety of applications. Careful evaluation of the machining

requirements will help to identify the appropriate cutting tool

necessary for the task.

When selecting cutting tools, manufacturers must consider the

unique properties of PCD and CBN inserts that differ depending on

the material and machining conditions. Users must be aware of the

tool requirements and specifically select cutting tools that will

meet those requirements within the desired limitations. Choosing

the right cutting tool is integral to machine operation.

Customization:

Support and Services:

Our PCD CBN Insert product comes with comprehensive technical

support and services to ensure optimal performance and customer

satisfaction. Our services include:

- Product selection assistance

- Customization options

- Technical consulting

- Training and education

- Installation guidance

- Maintenance and repair services

- Fast and reliable delivery

- Competitive pricing

Our team of experienced professionals is dedicated to providing the

highest level of support to our customers and helping them achieve

their production goals. Contact us to learn more about our

technical support and services.

Packing and Shipping:

Product Packaging:

- The PCD CBN Inserts are carefully packed in plastic cases.

- The plastic case is then placed in a cardboard box.

- The cardboard box is sealed with adhesive tape to prevent any

damage or contamination.

Shipping:

- The PCD CBN Inserts are shipped via reliable courier services.

- We ensure that the product is delivered to our customers on time

and in perfect condition.

- We also provide tracking information to our customers so that they

can track their shipment.

FAQ: