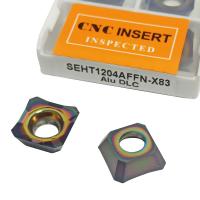

XEKT19M508FR Aluminum Milling Carbide Inserts 19M516FR 19M504FR

19M520FR 19M530FR MA Turning Tools

Products Description

Advantages:

- 100% Virgin Raw Materials

- German Dorst machine make perfect quality

- 3 times quality check before shipment

- Sharp edge high finishing

- Smooth chip removal

- Long-lasting wear resistant

- Improve working efficiency

- Excellent performace

Specification:

| Brand | Speed |

| Model | XEKT19M508FR/19M504FR/19M516FR/19M530FR/19M520FR |

| Color | DLC colorful coating, non-coated color |

| Type | Aluminum tools |

| Hardness | 20-60HRC |

| Usage | External Turning Tool |

| Material | 100% new tungsten carbide |

| Package | 10pcs/box |

| Processing type | Cnc machine process |

| Weight | 0.015KG |

| Workpiece | Aluminum, copper |

| Coating | uncoated, DLC coating |

Application:

Our XEKT tungsten carbide aluminum Insert adopts imported Dorst

machine to ensure good stability of cutting edge, high precision,

high hardness, good finish, steady performance, durable coating and

improves the working efficiency. And the carbide inserts are sharp

and thick, so that the cutting speed is fast but not easy to break.

The XEKT blade has smooth chip removal, higher hardness, sharp edge

finish, good toughness, long-lasting wear resistance, and economic

efficiency, low cutting resistance, high temperature resistance,

thermal shock resistance and oxidation resistance. It has wide

range of application, applicable to step surface processing, model

profiling processing, grooving cutting, slope processing. It can

process aluminum, copper and bronze, with high wear-resistant.

please send me your requirements to us, we will recommend the best

suitable grade.

Products Detail:

- Uncoated and DLC coating are available for your option.

- Aluminum inserts has high precision and high polished, it is

grinding piece by piece to guarantee the high precision.

- Choose the right coating for different material, unsuitable

machining conditions would reduce tools life.

Details:

1. Our perfect edge treatments as shown below, and every pieces can

stand the test.

2. Longer tools service life improve your work efficiency.

Production Line

Advanced equipments to ensure steady quality

1. We use imported German Dorst machine to produce, which with high

precision and smooth surface.

Insepction conducted in all production procedure

2. Each piece will have 3 times quality check before shipment, to

make sure stable quality.

Note:

1. XEKT aluminum carbide insert shall not be bumped or dropped on

the ground and please be handled with care.

2. Before installing the XEKT carbide blade, please confirm the

performance and use of operation table, and the cutting direction

indicated by the arrow of the blade is consistent with the rotation

direction of the operation table. Please pay attention to don't

install in the opposite direction. The wrong installation direction

may cause the blade serrations to fall off, in case of accidents.

3. After installation, it is necessary to confirm whether the

center hole of the XEKTcarbide blade is firmly fixed on the flange

of the saw table. If necessary, put on a spacer, then, push it

lightly by hand to confirm whether the blade rotates eccentrically.

4. When using, do not exceed the specified high speeds.

5. When not using, please hang the XEKT insert upright on a dry

rack.

Common questions:

1. Flank wear:

Effect: Gradual change in workpiece size or loss of surface

finishing

Reason: Linear speed is too high, and reach to service life of the

tool

Measures: Adjust the processing parameter, such as reducing the

linear speed and changing to inserts with higher wear resistance

2. Severely broken:

Effect: Sudden and unpredictable occurrence, resulting in scrapped

tool holder material or defective workpiece and scrapped

Reason: The processing parameters are set incorrectly, the

vibration tool workpiece or the insert is not installed in place

Measures: Set reasonable processing parameters. The feed rate and

cutting should be reduced, the corresponding machining insert

should be selected, and the rigidity of the workpiece and insert

should be strengthened.

3.Breakdown problem:

Effects: Sudden changes in workpiece size or surface finishing,

causes sparks and surface burrs

Reason: Inappropriate setting of processing parameters,

inappropriate selection of blade material, poor workpiece rigidity,

or unstable blade clamping

Measures: Check whether the parameter settings are reasonable, and

select the corresponding tool according to the workpiece

FAQ:

1. How is your quality?

Our products use Dorst machine imported from German, and each piece

will have 3 times quality check before shipment, so our quality is

very steady.

2.Can I have OEM service?

Yes, we can design the label as your brand, and you can choose the

box color.

3.How can I place order?

Please send inquiry to us directly, our salespeople will contact

you for order details. We can send order to you by air or by sea.