TNMG 160408 Finishing Inserts Tungsten Lathe Tools TNMG160408-PM

for Cnc Machine

Products Description

Advantages:

- 100% Virgin Raw Material

- German Dorst machine make perfect quality

- Smooth Surface

- Selected Materials

- Optional specification

- Excellent performance

- Sharp Edge

- High wear resistance

Specification:

| Brand | Speed |

| Model | TNMG160404, TNMG160408, TNMG160412 |

| Color | yellow, copper, black, blue nano, colorful coating |

| Workpiece | Steel, stainless steel, cast iron, Aluminum |

| Type | Turning Inserts |

| Package | 10pcs/box |

| Coating | pvd, cvd coated |

| Weight | 0.015kg |

| Usage | External Turning tool |

| Hardness | 20-65HRC |

| Material | Tungsten Cardide Inserts |

| Processing Type | Medium Cutting |

Application:

Our TNMG tungsten carbide Turning Inserts has high heat resistance

and cobalt rich gradient structure cemented carbide matrix makes

TNMG tungsten carbide inserts have a series of excellent properties

such as high hardness, wear resistance, good strength and

toughness. The TNMG blades are sintered at 5000 ℃ to remove

impurities, and sprayed by 1000 ℃ stress accumulation. The unique

coating process, fine and smooth, no drip marks, reduce surface

friction, so that the cutting resistance is smaller. And the

carbide inserts are sharp and thick, so that the cutting speed is

fast but not easy to break. It has wide range of application,

applicable to step surface processing, model profiling processing,

grooving cutting, slope processing, and could to be processed alloy steel, soft steel, carbon steel, medium steel, stainless

steel, cast iron, titanium alloy,

please send me your requirements to us, we will recommend the best

suitable grade.

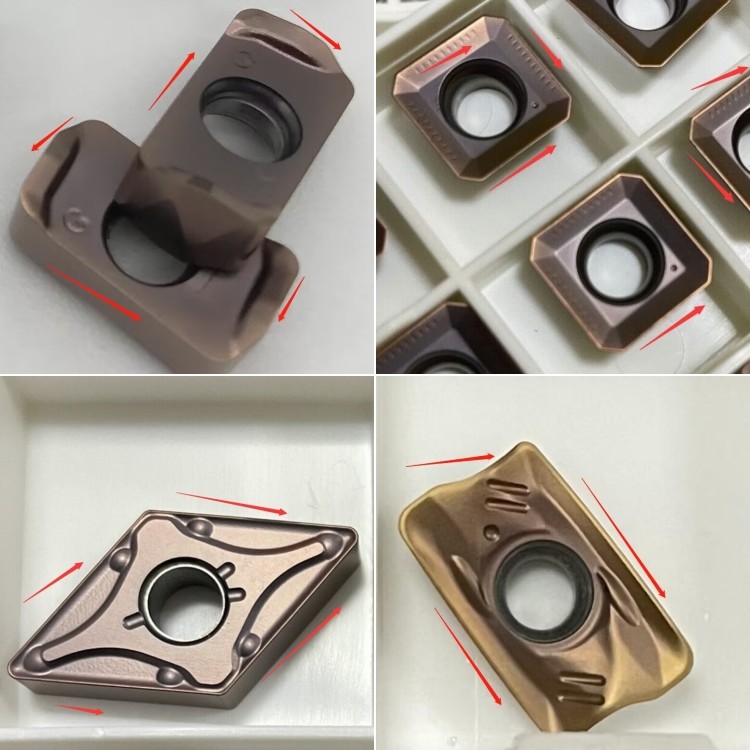

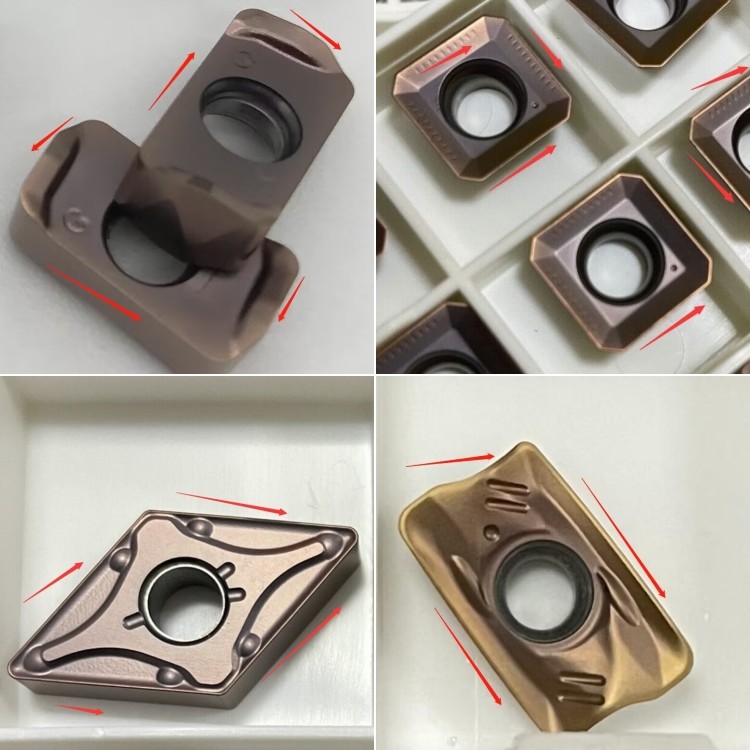

Products Detail:

- Chip Breaking and Chip Removal are Smooth of Each Patterns

- Coating Process with Stable Performance

- High Wear Resistance and Efficiency

- Usually black color for hard steel, yellow color for soft steel,

copper color for stainless steel, choose the suitable coating make your process more easier.

- Different angles are suitable for different processing

R0.4 Finishing Process

R0.8 Semi-finishing Process

R1.2 Roughing Process

Details:

1. Our perfect edge treatments, every pieces can stand the test.

2. Longer tools service life improving your working efficiency.

Company Profile

Hunan SPEED Carbide Tools Co.,Ltd is a professional supplier of

Carbide, Inserts,Including Turning Inserts,Milling Inserts,Grooving

Inserts,Threading Inserts,U drill lnserts, Aluminum Inserts and

Cermet inserts etc. Located in ZhuzhouHunan, which is the biggest

tungsten carbide tools city near ZCCCT, We provide various and

efficient delivery ways. Our factory covers and area of 2,000sqm

and has more than 100 staff members who are professional and

willing to grow up with you.

Below is our factory and warehouse, we use

1. 100% virgin raw material + Germany DORST machine make perfect

quality

2. each piece of insert have 3 times checked before shipment.

3. each piece will be finely grinding piece by piece

Feel free to contact if you want a factory show.

FAQ:

1. Flank wear: (This is a common form of failure)

Effect: Gradual change in workpiece size or loss of surface finish

Reason: Linear speed is too high, and reach to service life of the

tool

Measures: Adjust the processing parameters, such as reducing the

linear speed and changing to inserts with higher wear resistance

2.Breakdown problem: (bad form of failure)

Effects: Sudden changes in workpiece size or surface finish, causes

sparks and surface burrs

Reason: Inappropriate setting of processing parameters,

inappropriate selection of blade material, poor workpiece rigidity,

or unstable blade clamping

Measures: Check whether the parameter settings are reasonable, and

select the corresponding tool according to the workpiece

3. Severely broken: (a very bad form of failure)

Effect: sudden and unpredictable occurrence, resulting in scrapped

tool holder material or defective workpiece and scrapped

Reason: The processing parameters are set incorrectly, the

vibration tool workpiece or the insert is not installed in place

Measures: Set reasonable processing parameters. The feed rate and

cutting should be reduced, the corresponding machining insert

should be selected, and the rigidity of the workpiece and insert

should be strengthened.

4. Built-up edge:

Effects: Inconsistent workpiece dimensions and poor surface finish.

Fluff or burrs adhere to the workpiece surface

Reason: The cutting speed is too low, the feed is too low, and the

blade is not sharp enough

Measures: Increase the cutting speed and use a sharper insert for

the feed